Air Pump Vs Air Compressor – 5 Major Differences To Know!

TheToolGeeks.com is a participant in the Amazon Services LLC Associates Program and other affiliate advertising programs. We may earn from qualifying purchases. (Learn More).

Air compressor and air pump are two different tools that do the same job. Air compressors use a piston to squeeze air, while air pumps use an electric motor with rotating blades. We’ve highlighted major differences so that you may compare air pump vs air compressor.

We will explain how air compressors and air pumps work, how they are maintained, their prices, and their air pressure output to gain a better understanding of them.

Without further ado, let’s dive into the article to know more about the key differences between air compressors and air pumps and to understand air compressors and air pumps deeply.

Jump To Page Contents:

Air Pump Vs Air Compressor – Working

The main difference between an air pump and an air compressor is in the working. People use air pumps to move liquids as well as gases through some systems.

On the other hand, air compressors are used in the case of gases (only gases). An Air compressor is used to convert air into pressurized air.

No doubt, both instruments use high air pressure, but still, this difference is enough to make them two separate tools.

Air compressors are capable of squeezing the volume before transfer. By lessening gas’s volume, they pump it to whatever place you desire and one reason that air compressors aren’t suitable for liquids is that compressing them makes decreasing liquids harder and requires a lot of power.

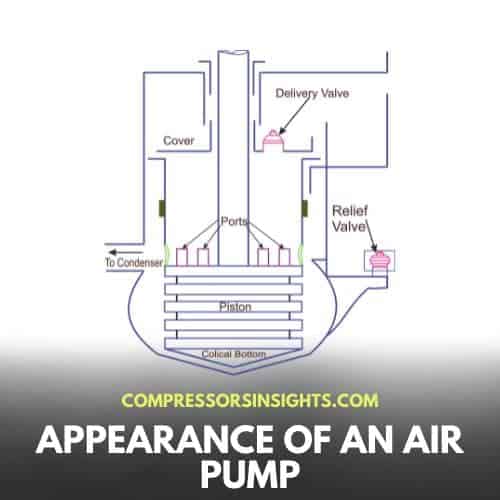

What Makes an Air Compressor Different From an Air Pump In Terms of Appearance?

When we compare air compressors vs air pumps, the major difference is their appearance and their necessities.

The air compressor comes with a motor, intake filters (which helps to make sure no dust can go in), valves (mostly compressors have 2 valves), storage tanks (the bigger the storage tank, the more work you do with it), drain, casing.

However, the air pumps have a motor, casing, volute, shaft, and impeller. To force air into the space the air pumps use pistons. It is a way to inflate.

Air Compressor Vs Air Pump – Output Air Pressure

Air compressors can produce up to 200 PSI, while Air pump is only capable of producing 30-50 PSI.

Air compressors’ high-pressure capacity makes them more suitable for heavy-duty work than air pumps because they need to use compressed gases in their applications.

Air Pumps are not so powerful as compared with Air Compressors but still, they have enough power to inflate tires and other appliances such as an irrigation system, etc.

Air Compressors Vs Air Pump – Prices

Air compressors cost around $100-$1000 whereas air pumps will be available at a cheaper price that varies from $20-$40.

We always recommend buying the highest quality product if you want your tool/machine to last long and give its best performance every time without any problem.

Air compressors have got lots of benefits over air pumps, so it is always better to buy an Air compressor rather than Air pump from any trusted brands or online sources.

Maintenance of Air Compressors Vs Air Pumps

Air compressor’s parts are more delicate than air pumps because they contain moving components (piston, crankshafts, etc) that require regular maintenance.

Air compressors need to be lubricated after every 120 hours of working or at least once a year depending on the usage and work conditions. Air compressor requires high-quality oil for lubrication purposes but it can use low-quality oils too.

However, you should always buy the highest quality products according to your budget so that you don’t have to face any problems while using them in the future without wasting money on cheap brands/products.

There are two types of air pumps: manual and digital. The manual one is even easier to maintain than the digital type, as all you need to do for maintaining your pump’s operation is check it regularly and make sure that weather conditions stay at a set point before deciding if repairs or other maintenance (such as oiling) needs doing.

Air pumps don’t require any maintenance and you can use them as long as they work properly. Air compressor needs a professional for proper servicing and maintenance whereas an air pump doesn’t need such kind of services because it’s easy to maintain yourself without wasting money on expensive professionals’ fees.

Conclusion

This article is about air pumps vs air compressors. How do pumps and air compressors work? How they differ from each other, what their prices are, and how they should be maintained. Air compressors are used only for gases.

However, the air pump is used for both liquid and gas. The air compressors and air pumps both are capable of high pressures. The air compressor comes with valves, casing, motor, filters, and storage tanks.

On the other hand, the air pump comes with a motor, casing, and impeller, volute. The air compressors are very powerful. They can pull up to 200 PSI, whereas the air pump does not have enough power. The air compressors are relatively high-priced, and air pumps are good enough in price.

FAQ’s

Which Air Compressor or Air Pump is right for me?

A compressor is ideal for a compressed vapor that can easily compress or move fuel vapor. If fluid or vapor flow is required this air pump should suffice.

Can We Replace the Air Pump with an Air Compressor?

An air compressor is a machine that compresses the air in it to make compressed air powerful whereas an air pump is a device or equipment which moves fluids through it.

Air pumps are not able to generate compressed gas for use in industries and workshops where pressure, temperature, etc need high-quality machines/tools for their applications.

Air Pump can be used efficiently as long as it is working properly with good quality but Air Compressor will require proper servicing from professionals if something goes wrong during operation because they contain moving parts inside them that need regular maintenance and cleaning services after every 120 hours of work depending on the usage conditions.

What is a Vacuum Pump?

Vacuum pumps are mechanical systems that are utilized for vacuum creation. Essentially this involves the removal of gases and air at a regulated level to provide safety and the sanitary transportation of liquid. Although it can even travel in some way in the transport of gases.

Vacuum pumps are widely used throughout home and business environments. It is possible that vacuum pumping is installed in any room if the air is moving from the same area to the other with a very high risk.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.