10 Major Oil-Free Air Compressor Pros and Cons For You!

TheToolGeeks.com is a participant in the Amazon Services LLC Associates Program and other affiliate advertising programs. We may earn from qualifying purchases. (Learn More).

If you’re looking to buy an air compressor for your project and you’re confused between oil-lubricated and oil-free compressors, then this article is for you. We’ve highlighted Oil-free air compressor Pros and Cons for you.

We’ve also compared Oil-free and Oil-lubricated compressors and highlighted some of the applications where these compressors are used. So, read through this article, and you’ll end up deciding which one is best for you.

Jump To Page Contents:

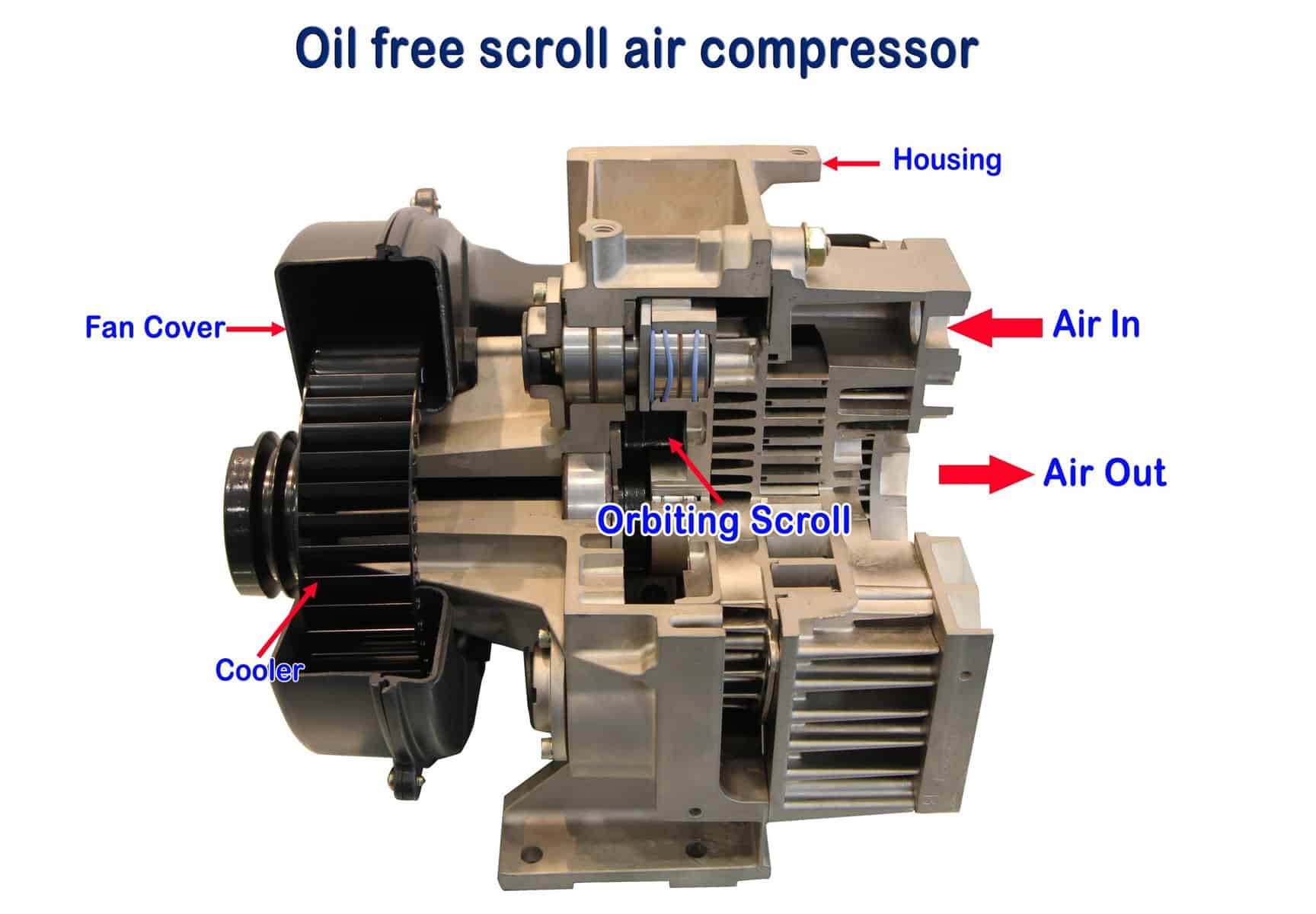

What is an Oil-Free Air Compressor & How Does it Work?

An oil-free air compressor does not need to be lubricated with oil. The compressors are inexpensive and compact and eliminate the need for in-line filtration and the risk of oil contamination.

The compressors take outside air from the unloader valve and pass it through an inlet air filter to clean the air.

Oil-Free Air Compressor Pros and Cons

Advantages of Oil-Free Air Compressor

1. Maintenance:

One of the advantages that an oil-less air compressor gives is that it does not require maintenance, and these compressors do not require routine oil and oil filter changes as it is pre-lubricated.

2. Clean Air:

Clean air produced by oil-less air compressors is ideal for laboratories, surgeries, food packaging, and beverage dispensing.

3. Cost-Effective:

The oil-less compressor is cost-effective, which means it is inexpensive. If you need a compressor for small projects, you can easily save money by buying an oil-free compressor.

4. Reduced Energy Consumption:

The oil-free compressor does not generate air, which will pollute the atmosphere.

5. Less Weight:

The oil-free compressor is small in size and lightweight. It does not require a lot of people to handle it, and one person is enough to carry it around.

6. Compact Design:

The oil-free compressor is a compact design compressor, which means it is small in size and does not require a lot of space. It can work with tools and can have a big tank.

7. Easy to Operate:

The oil-free compressors are easily operable. They do not need professionals to assemble it and then understand it, and the owner can easily understand it and use it.

Disadvantages of an Oil-Free Air Compressor

1. Not Durable:

Oil-free air compressors are not very durable, but they are less expensive. Despite this, they get dry due to being pre-lubricated, which shortens their lifespan. Mostly they only last for a maximum of 18-months.

2. Noise Issue:

An oil-free compressor does not get maintenance, so when it starts to dry out, parts of the compressor rub together, creating noise.

Modern compressors are much better than older ones since they do not sound as bad. It is because of soundproofing and dampening techniques used in it.

3. Not Suitable for Heavy-Duty Tasks

The oil-free compressors are not for heavy work, and they are capable of industrial work, and they can only do crafting, inflating bike tires, cutting, etc.

What is an Oil-Lubricated Air Compressor?

An oil-lubricated air compressor is an industrial air compressor that requires oil to function. These air compressors can handle heavy loads, making them dependable and efficient, and these compressors are more durable.

Oil-Free Air Compressors Vs. Oil Air Compressors – Major Difference

Oil-Lubrication – The oil-free air compressor needs no oil lubrication to work, and the compressor is pre-lubricated. It is necessary to change the oil in the oil-lubricated compressor regularly, as it is an oil-lubricated component.

Maintenance – The oil-free compressor does not require regular maintenance, and the oil-lubricated compressor needs regular maintenance.

Air Filtration – The oil-lubricated compressor needs more air filtration to protect the compressor from contamination.

Lifespan – The oil-free air compressor has less lifespan than oil-lubricated air compressors.

Noise level – The noise level of the oil-free compressors can be louder.

Workload – The oil-lubricated compressor is capable of handling heavy work. So for industrial and heavy-duty tasks, you should go for it.

| Products | Product Name | Details | Price |

|---|---|---|---|

Best Choice | Best Choice |

| Buy On Amazon |

Our Second Pick | Second Pick |

| Buy On Amazon |

iSpray Technology | iSpray Technology |

| Buy On Amazon |

Small but Powerful | Small but Powerful |

| Buy On Amazon |

Professional Sprayer | TProfessional Sprayer |

| Buy On Amazon |

Oil-Lubricated or Oil-Free: Which One is Suitable for You?

An oil-free compressor is a portable air compressor that is not expensive, light, and easy to use. It requires less maintenance and does not last long because it is pre-lubricated.

Oil lubed compressors are heavy-duty compressors. They are more durable compared to oil-free compressors.

According to your needs, decide what is more suitable for you. For general use, an oil-free one is fine.

Applications for Which Oil-Free Air Compressors are Good

The oil-free compressors are not industrial air compressors, and they are not capable of handling heavy work. Some of the applications of these types of air compressors are:

- Oil-free compressors are used for inflating vehicles and bicycle tires.

- Suitable for powering airbrushes.

- Powers pneumatic processes for factories and manufacturing plants.

- Supports cutting, sanding, nail guns, painting, and crafting.

Applications in Which One Should Use an Oiled Air Compressor

If your project type is mentioned below, then we recommend you choose oil-lubricated models for your job:

- Industrial Applications and Heavy-duty Applications

- The oiled compressor is used for food and beverage processing.

- It works best for the pharmaceutical manufacturing industry.

- Helps in operating ventilators, Supports surgical equipment.

- Supports construction by giving a range of tools.

- Supports agriculture, for spraying crops, etc.

- Pumps water at high pressure for pressure cleaners and water blasters.

Oil-Free Air Compressor Life Expectancy

The oil-free air compressors are ideal for price and maintenance. However, the compressor’s lifespan compared to the oil-lubricated compressor is less. The compressor lasts only about 200 hours, or in case the compressor has higher-end units, it lasts 2000 hours.

The new oil-free compressor performs much better than the old oil-free compressors. The compressors can last about 18 months. When a compressor loses its efficiency, most people buy a new one.

How to Maintain an Air Compressor?

User Manual – Maintain the compressor by keeping and reading the manual. It helps the owner to get some information in case of any trouble.

Nuts and Bolts – During operation, the compressor vibrates, which causes the nuts and bolts to loosen. Ensure to check them.

Intake Valves – Intake valves. When air goes through them, dust particles enter. Ensure to clean the intake valves to ensure the compressor does not become a burden.

Hoses – As the hose transfers air from the compressor to the endpoint, it is the most crucial part. The hose needs to be loose and flexible yet tight. Inspect the hoses to maintain the compressor.

Air Filter – Filters remove dust from the air to handle heavy loads. If the air filters are not clean, the compressor will not perform well.

Drain the water from the tank – water in the tank can cause moisture that can cause problems with the compressor’s efficiency. Also, moisture can enter the other parts of the compressor, which can cause rusting.

Clean fuel tank – Annually clean the fuel tank as it can become poisonous if you do not clean it. The particles can lead to being toxic over time.

Verify the power-off system – When the power supply trips or the machine gets too hot, the automatic power-off feature automatically helps the device shut down. Ensure that the button is in good working condition to save the compressor.

SneakPeek at the Pros & Cons of an Oil-Lubricated Air Compressor

Advantages:

- The noise level of the oil-lubricated air compressor is low.

- The compressor has a long life span.

- Works for heavy-duty workers.

Cons:

- The oil-lubricated compressors are costly.

- The compressors are heavy and are bulkier.

- The compressor needs maintenance at regular intervals.

Conclusion

By comparing oil-free air compressors’ pros and cons, you can easily decide whether to purchase them or not based on your needs. The oil-free compressor is not a burden for the owner as it is pre-lubricated and does not need regular maintenance.

The oil-free air compressor is not an industrial air compressor, it cannot do heavy-loaded work, and the compressor’s lifespan is also not much longer.

According to your needs, you can decide what compressor you need oil-free or oil-lubricated as one can do heavily loaded projects, and the other is great for small projects and is transferable.

FAQ’s

Are oil-free air compressors better?

An oil-free air compressor is useful for industrial purposes and works longer hours. Oil-lubricated compressors are better because they last longer, Oil-free only works for a small span, and it is great for domestic use.

How do I maintain my oil-free air compressor?

Maintaining an oil-free compressor is not that difficult. You need to keep the compressor by regularly inspecting the power lead, draining the compressor’s air receiver, monitoring the pressure, observing the compressor, checking leaks.

Amazon and the Amazon logo are trademarks of Amazon.com, Inc, or its affiliates.